Description

Overview

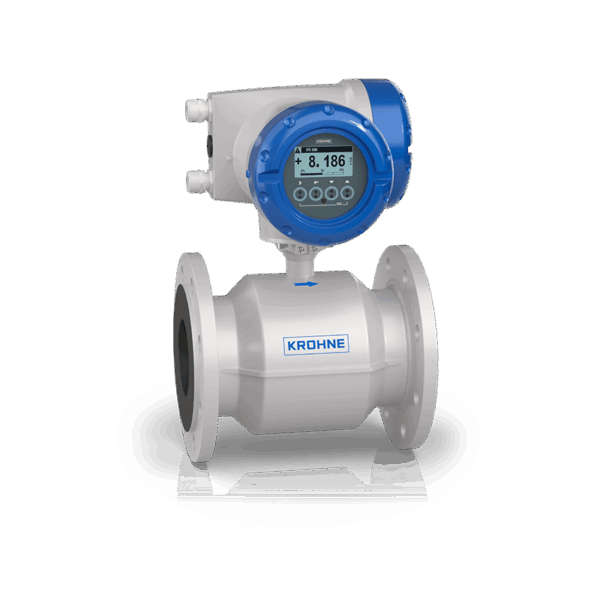

The OPTIMASS 3400 is a cost-effective Coriolis mass flowmeter for accurate flow measurement of liquids and gases in a variety of demanding low flow and dosing applications (from 0.3 kg/h or 0.01 lb/min upwards). The OPTIMASS 3400 features Entrained Gas Management (EGMTM) for liquid applications and thus maintains operation even with entrained gas of up to 100%.

The OPTIMASS 3400 features a single Z-tube design which guarantees a low pressure drop across the meter. The device is available with NPT connections, a range of flange connections as well as standard hygienic connections. Like with all other KROHNE Coriolis mass flowmeters there are no installation restrictions as the OPTIMASS 3400 is not affected by crosstalk/line vibrations and can thus be installed in series or in parallel. The Coriolis meter is approved for use in hazardous areas. It offers various diagnostic functions (NE 107) and digital communication options. Via the OPTICHECK Flow Mobile app all device settings can be managed on-site via a secure Bluetooth® connection. In this way, a variety of commissioning tasks, e.g. zero calibration or configuration of diagnostics, can be done wirelessly.

Product features and options depend on device configuration: Contact us to make sure that your preferred functionality can be combined in one device.

- Single Z-tube design

- Entrained Gas Management (EGMTM): maintains operation with air or gas entrainments in the medium

- Device commissioning, verification, diagnostics and monitoring via a secure wireless Bluetooth® connection (<20 m / 65.6 ft)

- Fast and completely digital signal processing

- High accuracy: ±0.1% of MV for liquids / ±0.5% of MV for gases

- Extensive sensor and process diagnostics (incl. NE 107)

- Integrated temperature measurement

- 3 sizes in a single footprint

- Optional PED approved secondary pressure containment up to 30 barg / 435 psig

- Many options (heat tracing, purge port etc.)

- Easily drained and easy to clean

- No crosstalk: resistant to installation and process effects

- On-site verification of flowmeter with OPTICHECK service tool