Description

Overview

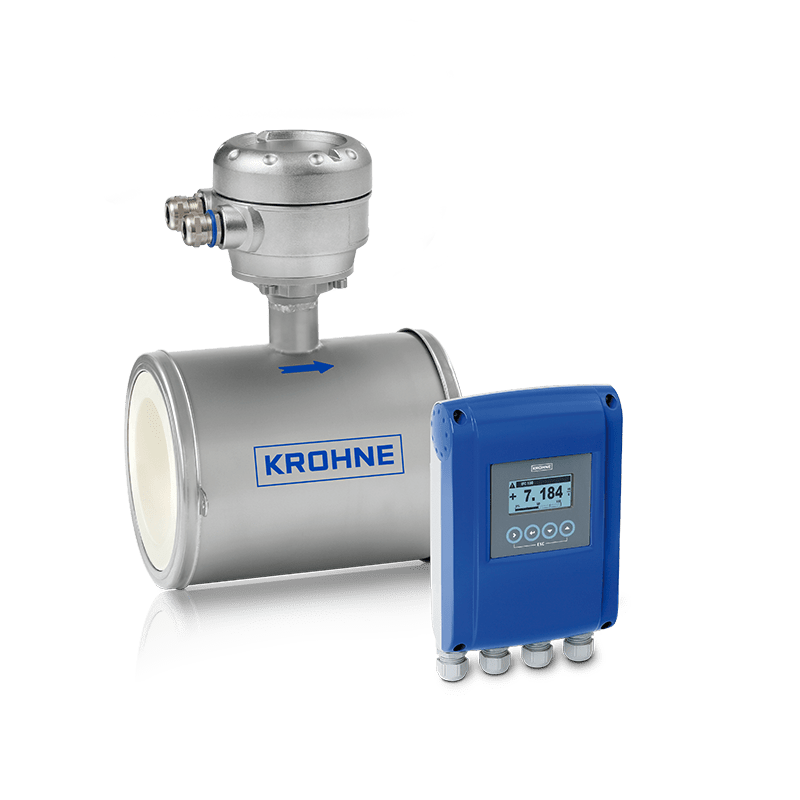

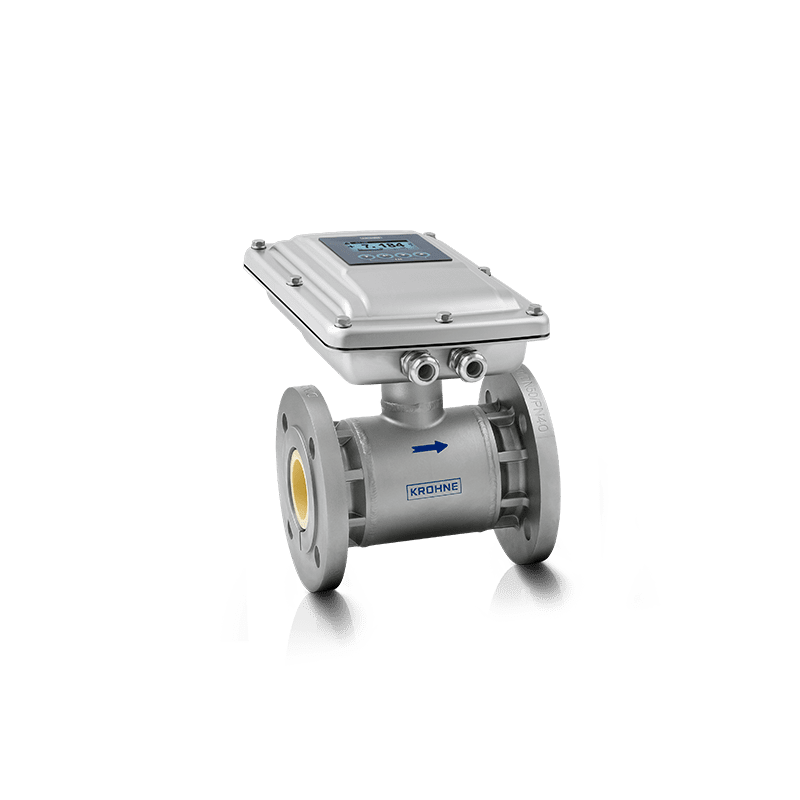

The OPTIFLUX 5100 is an electromagnetic flowmeter (EMF) with a high-tech ceramic measuring tube for demanding process flows. It is particularly suited for applications in the chemical processing industry, the minerals and mining sector as well as in any other sectors of industry where highly aggressive or abrasive liquids occur. The EMF is the ideal solution for harsh process conditions with temperatures up to +180°C / +356°F, aggressive chemicals and solid content (up to 10%).

Thanks to the unique combination of material properties such as surface hardness and finish, mechanical strength, resistance to corrosion and temperature shock, the OPTIFLUX 5100 outclasses all traditionally lined EMFs. The flowmeter comes with flange or as flangeless and space-saving wafer version. Both versions are vacuum-resistant and comply with the Pressure Equipment Directive. The OPTIFLUX 5100 is approved for use in hazardous areas. A full on-site verification of the flowmeter without process interruption can be carried out using the OPTICHECK service tool.

Product features and options depend on device configuration: Contact us to make sure that your preferred functionality can be combined in one device.

- Bi-directional flow measurement over a wide dynamic range (turn down ratio: 1000:1)

- Withstands highly aggressive and abrasive fluids

- Fully vacuum-resistant with high-tech ceramic sensor material

- Fused in-place Cermet or platinum electrodes

- First EMF with ceramic measuring tube to comply with the Pressure Equipment Directive

- High resistance to corrosion and temperature shocks

- Diagnostics incl. conductivity, electrode error, ambient and process temperature etc.

- Standard measurement accuracy: ±0.3% or ±1mm/s of measured value (MV)

- Available as flange or sandwich (wafer) version

- No moving parts, no wear, no pressure loss

- On-site verification of flowmeter with OPTICHECK service tool