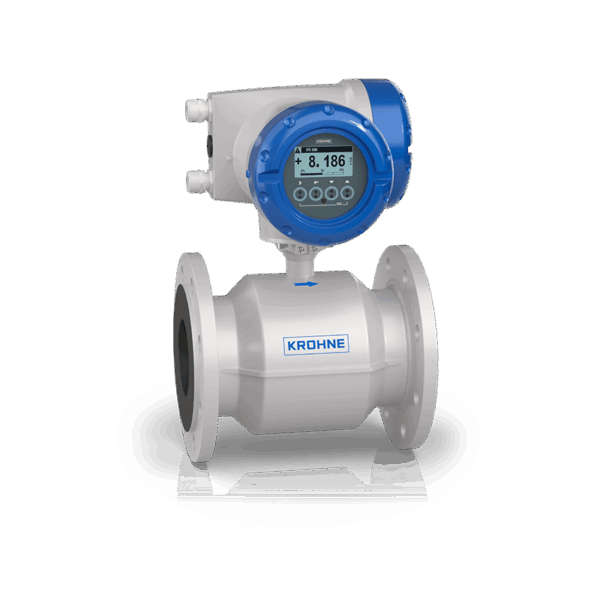

Description

Experience Meets Innovation

The Coriolis Mass Flow and Density Meters with superior performance under demanding conditions.

The successful Rotamass series has been progressively developed and is also newly equipped with the latest technology. This meter delivers unsurpassed performance for demanding and critical applications with superior aeration handling and advanced diagnostic functionality.

- Typical Applications

- Batching

- Burner control

- Feed and product control

- Filling and dosing

- Gas void fraction

- In-line concentration and density

- Loss control

- Material and mass balance

- Net oil computing

- Process control

- Solvents

- Water cut